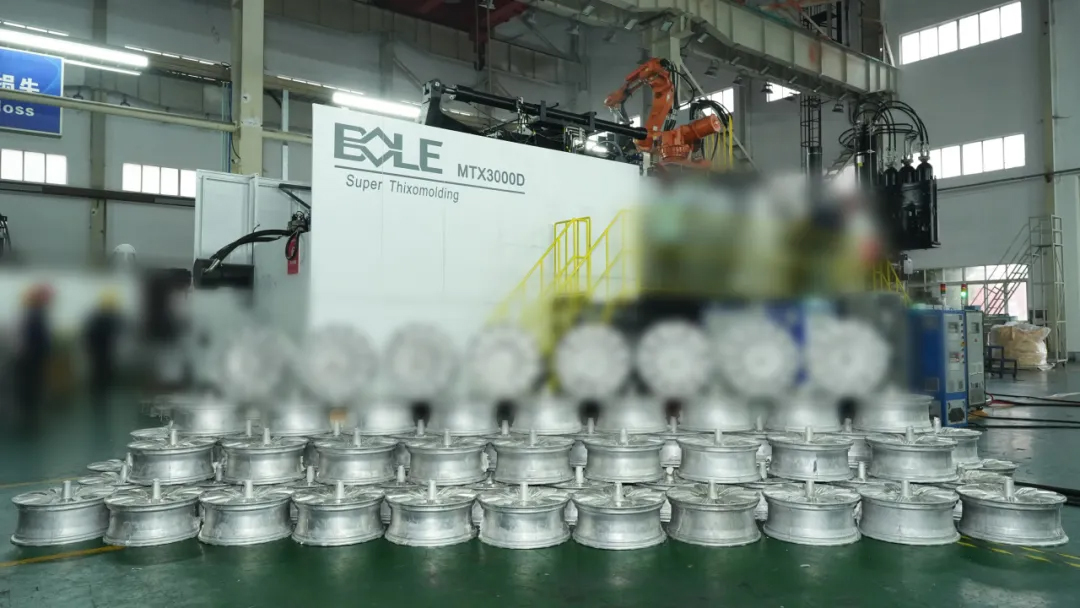

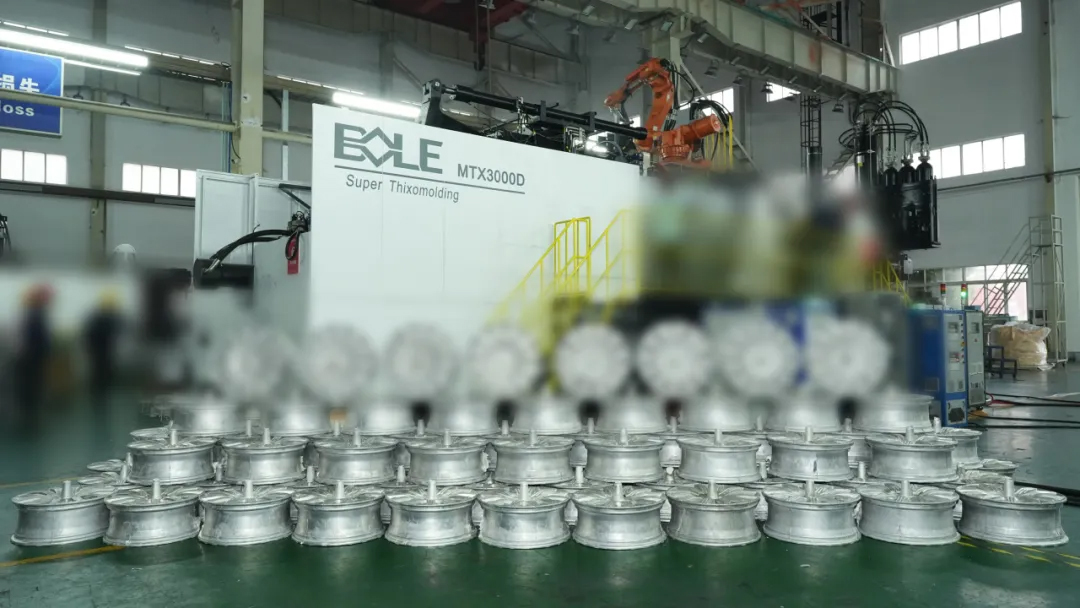

Recently, China's high-end equipment manufacturing field again spread good news! The 3000T super large semi-solid magnesium alloy injection molding machine independently developed by BOLE successfully completed the world's first 20-inch integrated magnesium alloy wheel with a single weight of 16kg+. This breakthrough achievement not only refreshes the application record of semi-solid molding process in the field of large-size and lightweight automotive parts, but also sets a new benchmark for the lightweight process of global new energy vehicles.

This success marks:

1.Cost revolution: Compared with the traditional forging process, the production efficiency is increased by 5 times, and the single cost is reduced by 50%, so that the magnesium alloy wheel has large-scale commercial value for the first time;

2.Technology independence: Bole 3000T equipment to achieve 100% localization, breaking the technology monopoly of Japan, Germany and other international giants;

3.Zero-carbon manufacturing: The production energy consumption is only 60% of the low-pressure aluminum alloy casting, and the carbon emission reduction of the whole life cycle is more than 35%.

As a core component of automotive lightweight, magnesium alloy wheels not only fill the gap in the global semi-solid molding process in the field of large-size lightweight automotive parts, but also mark the industrialization of magnesium alloy application into a new stage. BOLE will continue to optimize semi-solid injection molding technology to help the global automotive industry achieve more efficient energy conservation and emission reduction goals.

During 26th -28th 2025 The 20th China International Die Casting Confer...

>

Recently, China's high-end equipment manufacturing field again spread ...

>

BOLE MACHINERY, a global leader in injection molding solutions, succes...

>