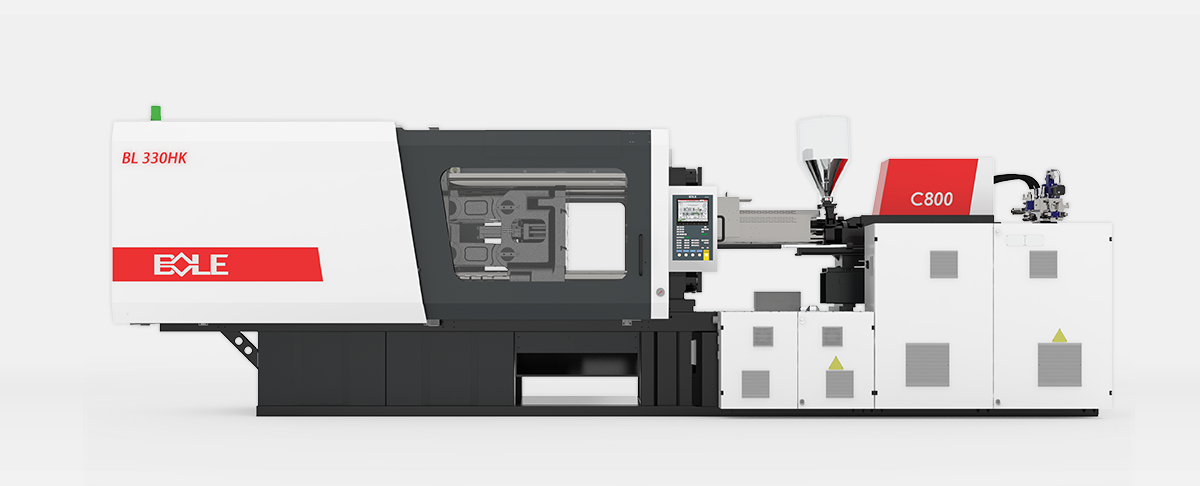

Based on standard structure, HK clamping structure will be

improved by 100% on mould platen rigidity, tie bar rigidity

and frame rigidity.

HK injection unit is with special single injection cylinder design

and injection rod is not rotatingwith screw, which will be no

oil leakage risk.

HK injection speed is from 350mm/s to 600mm/s, which can

meet the package and zip tie

molding requirement.

HK whole series machine is equipped with BECHHOFF

controiler, which is imported from German.

The response time is 12.Sms.

Equipped with SM third generation low inertia servo system,

minimum response time can be

35ms and save energy 50%.

Equipped with multi-grade eject function, pulse eject function available.

DESCRIPTION

DESCRIPTION