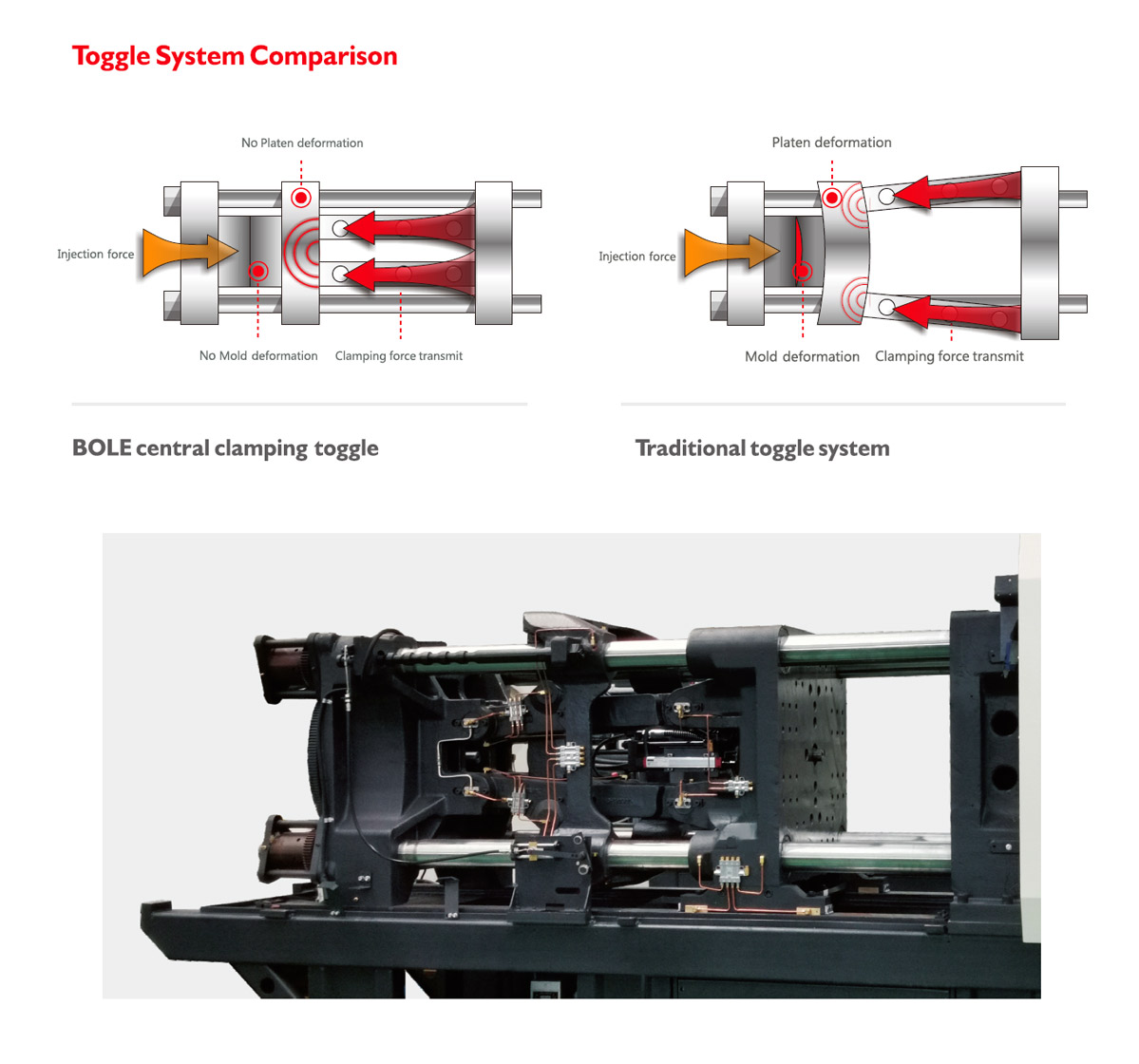

After sample survey, clamping force efficiency of BOLE central clamping toggle design can reach 100%, Clamping force efficiency of traditional edge clamping force only can reach 80-85%.

BOLE central clamping toggle design can save 2-5% material for 80% of custome

Repetitive positioning accuracy of mold

opening & closing:± 1mm

Product weight repetitive accuracy:≤0.5%

Less possibility of flash, and save flash trim process

The latest design of clamping structure, averaged force and less distortion for mould platen. Precise low- pressure function for mould closing, proportional pressure control, iso-stress mould platen design, to extend mould life.

Central clamping structure can provide bigger opening stroke&ejection stroke than other brands' stroke, and can install larger molds easier (Especially for deep cavity working condition.)

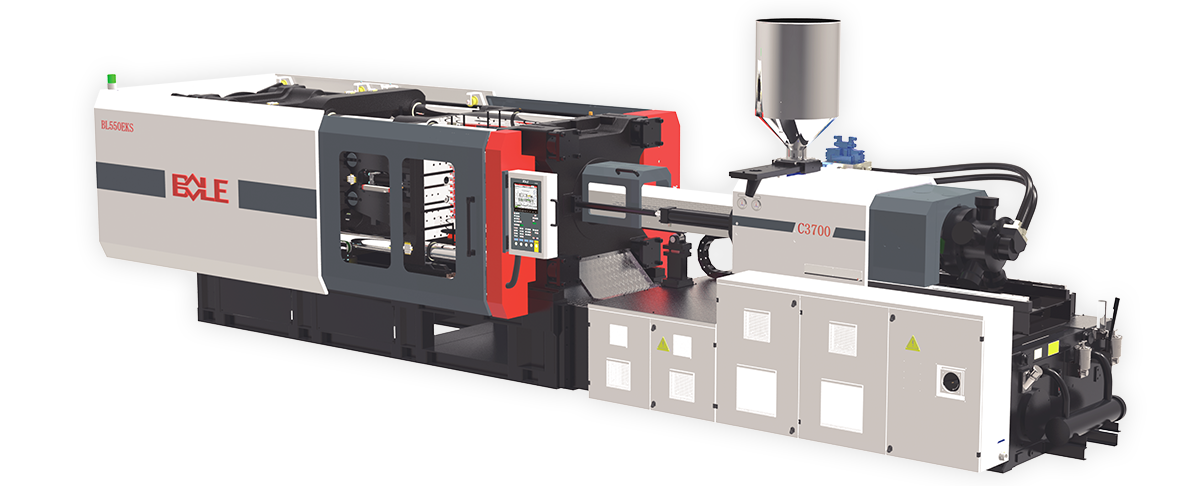

DESCRIPTION

DESCRIPTION Drive system

Drive system

EKS centre clamping structure was design and stimulate by professional software, over structure rigidity increased by 30%.

>

Offer high precision, high performance,more stable solution for lnjection moulding machine.

>